Morgan advanced materials certech has 45 years experience in the design and production of complex ceramic cores and wax patterns for challenging industrial casting applications all over the world.

Ceramic cores for turbine blades.

To meet those goals new turbine blade designs are needed that have complex internal cooling passages that allow the blades to withstand the higher operating temperatures required for improved performance.

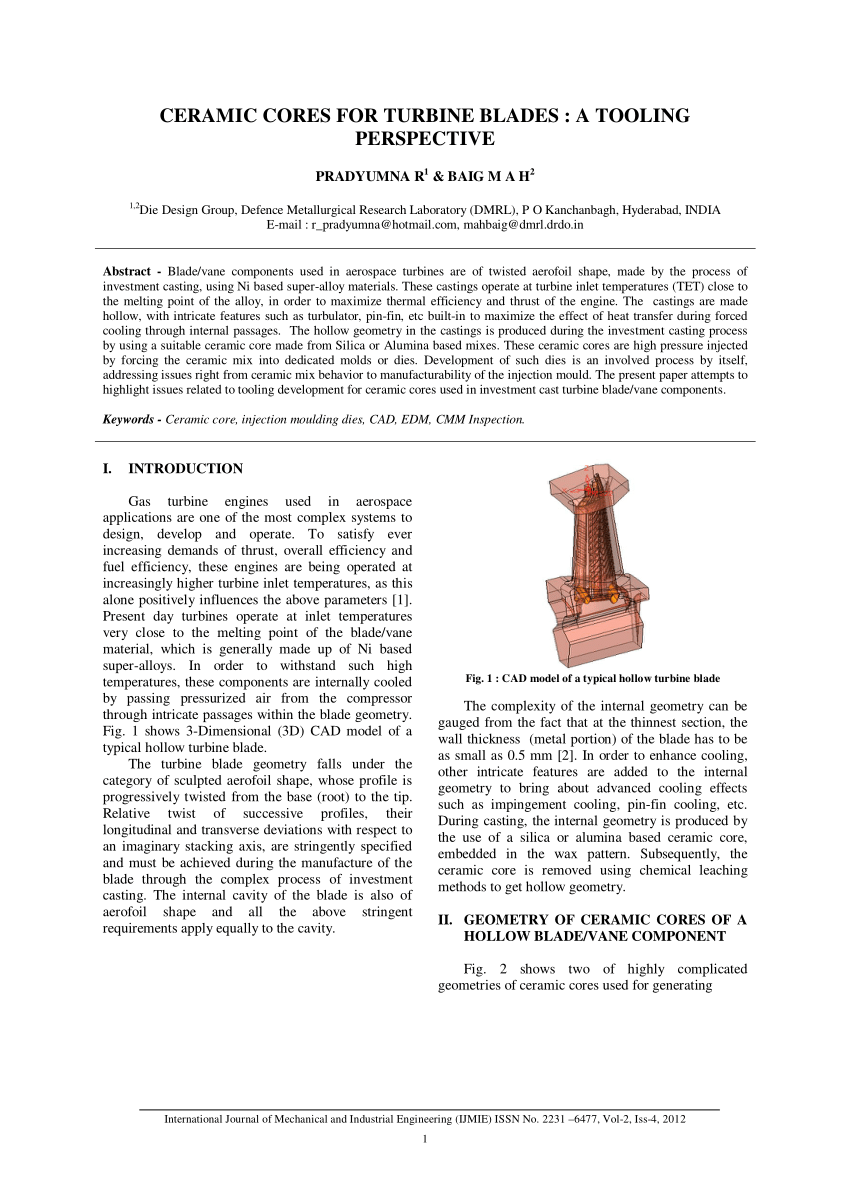

The hollow geometry in the castings is produced during the investment casting process by using a suitable ceramic core made from silica or alumina based mixes.

These ceramic cores are high pressure.

Traditionally fabrication of the ceramic cores involves time consuming procedures and low processing flexibility.

Ceramic cores are utilised for shaping internal cooling canals in the process of turbine blade casting which positively influences the turbine engine efficiency.

Gas turbine engines used in aerospace applications are one of the most complex systems to design develop and operate.

Ceramic cores are used during the investment casting process to produce those internal passages.

Keywords ceramic core injection moulding dies cad edm cmm inspection.

A ceramic core for use in casting a turbine blade and defining the internal cooling passages therein said blade having a tip root pressure side suction side leading edge and trailing edge.

Our cores are a critical component in the manufacture of complex castings for aircraft engine turbine blades vanes and associated cast components.

The main advantage of cmcs over conventional superalloys is their light weight and high temperature capability.

Highlight issues related to tooling development for ceramic cores used in investment cast turbine blade vane components.

Currently directional column and single crystal hollow turbine blades for aero engines use ceramic cores with high performance e g silica alumina.

In investment casting ceramic cores are used to form intricate internal cooling passages of gas turbine blades they are mainly fabricated by injection moulding ford 1997.