Ns industries is a distributor of american made pressure tubing including boiler tubes condenser tubes heat exchanger tubing boiler pipe ferrules boiler tube plugs.

Ceramic ferrules for heat exchanger.

The panel members will present a brief summary of the past integrity issues state of the art solutions and.

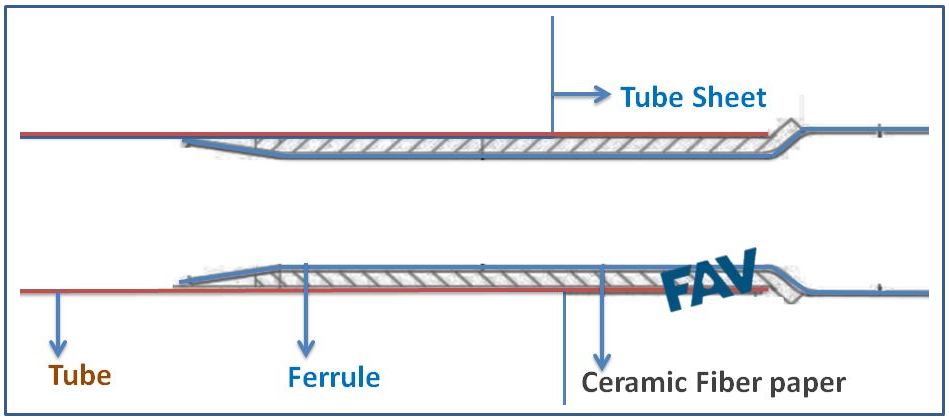

The design does not have any metal to metal contact from the ferrule to the tube sheet or the heat exchanger tube.

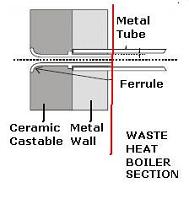

Ceramic ferrules are used at the inlet of the shell tube type heat exchanger to protect the tube inlets from hot gas corrosion and abrasive particle erosion.

Ceramic ferrule for waste heat boilers the waste heat boiler whb is arguably the most fragile part of an sulfur recovery unit sru and is subject to sudden and very costly failure.

Tube inserts and tube ferrules are a metal plastic or polymer inserted into the end of a heat exchanger tube to provide protection to the tube mouth ends of a shell tube type heat exchanger.

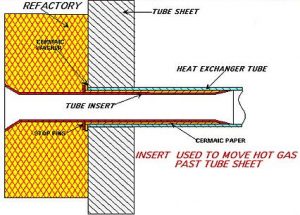

To bring a hot tube side fluid past the inner face of the tube sheet 3.

To carry tube side fluid through a ceramic or heat resistant tube sheet coating we also manufacture ferrules of different types as per.

To protect tube ends from the effects of turbulence 2.

The ferrules can be removed inspected and if necessary sent back to the factory for new ceramic fiber paper and taping before returning to the unit.

The sru waste heat exchanger boiler continues to be a significant operational integrity consideration.

Ferrule design and installation for insulation of sru tubesheets domenica misale lyttle.

Reliable oxytron oxide bonded silicon carbide wear resistant and high temperature ferrules are designed to be inserted in heat exchangers.

Tube inserts and tube ferrules are a metal inserted into the end of a heat exchanger tube to provide protection to the tube mouth ends of a shell tube type heat exchanger.

Techno cera ferrules are manufactured using 98 high alumina.

These ferrules exhibit excellent mechanical wear resistance corrosion resistance and thermal.

Ceramic ferrules for boilers.

The requirement for this ferrule arises as all tube failures occur within the first few inches of the heat exchanger tube inlet end.

Only the ferrules that are worn out the need to be replaced.

Tube insert and ferrule are the same products a metal plastic or ceramic tube that is inserted into the end of a heat exchanger tube to provide a specific function.

The purpose of a tube insert is to either be sacrificial to the effects of inlet end erosion corrosion impingement to induce a fluid to fall on the id of a tube in a falling.

Engineered with thin walls tapered inlets and precise tolerances they serve to protect the weld integrity and first several inches while absorbing the brunt of the heat produced from the process.

Both in the inlet and outlet ends.

The solution to this situation is the use.

The most common failure is the tube to tubesheet joint where temperature can become unacceptably high causing the welds to fracture and the joints to fail.