The densification mechanism of ceramic particles under high pressure sintering starts with plastic period following by grain boundary sliding and diffusion as is reported in refs.

Ceramic deformation behavior under compression.

Materials and methods 2 2 uniaxial tension.

The objective of this research is to explore the deformation behavior and fracture process of the sic under uniaxial impact loads.

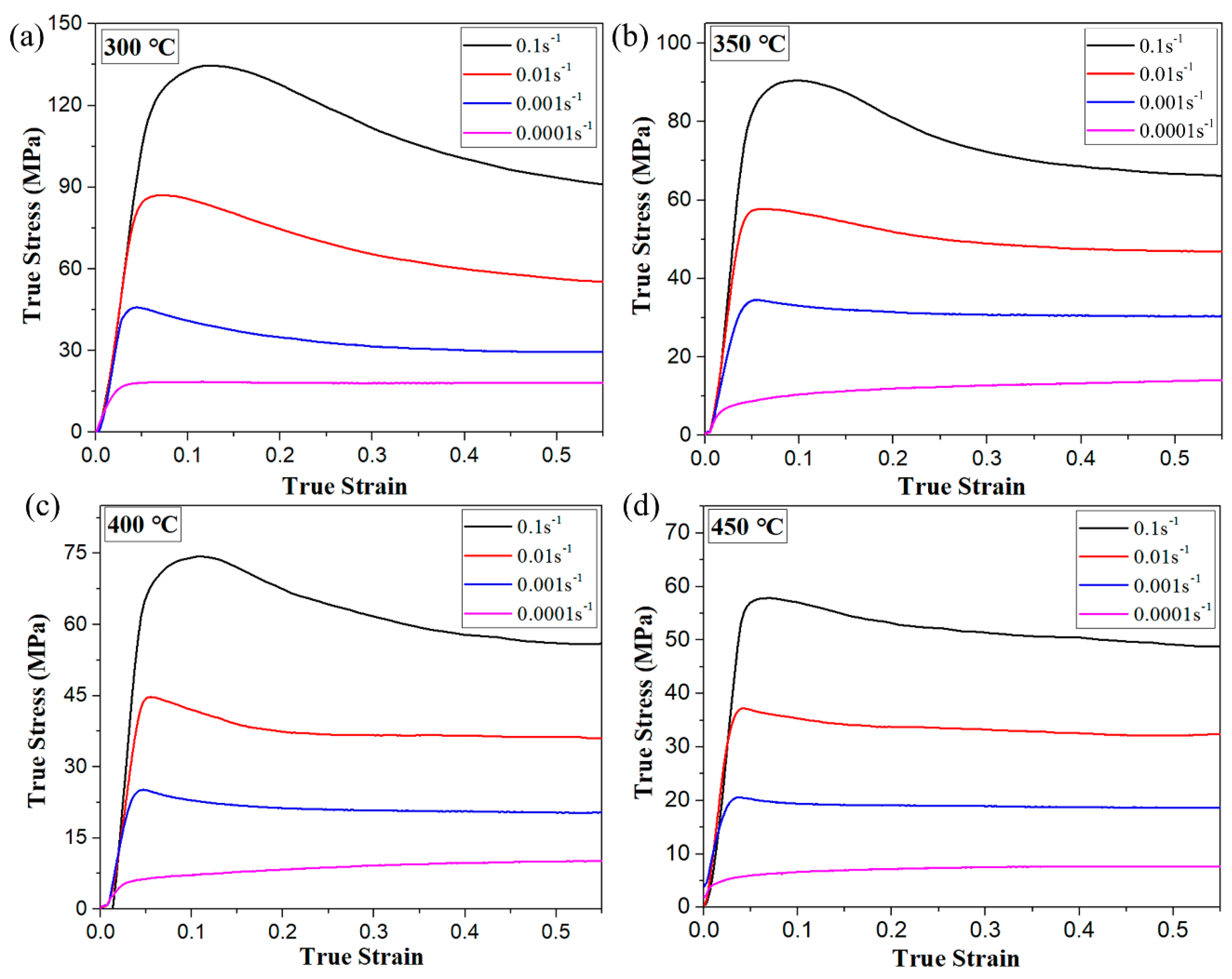

The stress strain behavior of the four metals under compression is shown.

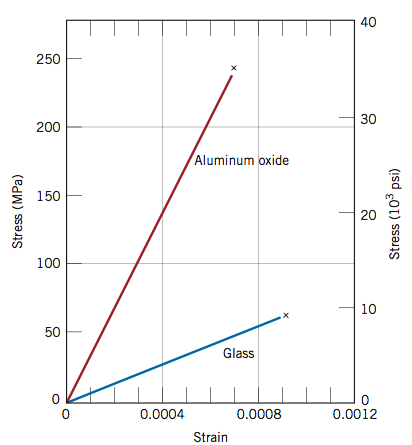

Implying an elastic deformation process under cold compression.

Covalent bonds of a ceramic will resist deformation when a force is applied but break when the threshold is passed whereas the delocalized nature of the bonds in metals allows for plastic deformation or ductile behavior.

While ceramic powder exhibits special densification behavior during compression.

The difference in deformation behavior between homogeneous pillars and multilayer pillars along with other geometric effects were examined in detail.

In this way the cct was simulated.

The compressive deformation and failure behavior of ceramics and ceramic metal composites for armor applications has been studied as a function of strain rate at los alamos national laboratory.

This study is an attempt to investigate the mechanical behavior of proppant packs deforming under compression loading.

Therefore debate continues on the dynamic deformation behavior and the underlying micromechanisms even for the same ceramic with different fabrication processes.